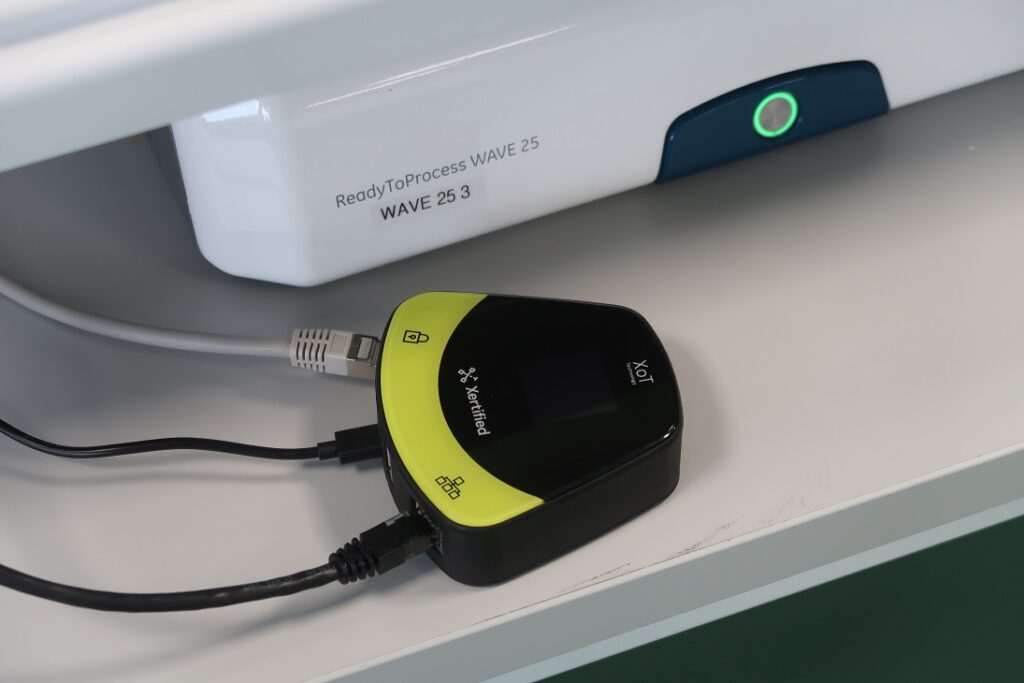

Xertified XoT devices to secure life science equipment

It was obvious from the first meeting that there is a case for Xertified to secure vulnerable life science equipment. Promising cyber security improvements in fifteen minutes or less seemed like an interesting promise, stretching what I thought was even possible. One week later we are all much wiser, this is what we learned. Xertified […]

Xertified XoT devices to secure life science equipment Read More »