The spider web’s strength and elasticity make it a fantastic material with many desirable properties. It is made up of proteins, which make it useful for repairing damaged tissue in the body. For example, it is known that the cardiac musculature is often destroyed during a heart attack. Spider silk can, in this case, be used as a supporting network to which one can attach cardiac muscle cells to repair the damaged area. The use of silk proteins for tissue reconstruction has a wide-ranging potential, including for example wound healing and repair of nerve injuries.

“The biomaterial we produce is a recombinant spider silk protein with a variety of unique, desirable properties. Here at the Testa Center we have purified the recombinant protein and our goal is to investigate the possibility of scaling up our current process,” says Jenny Rönnmark, Production and Quality Manager of the company Spiber Technologies.

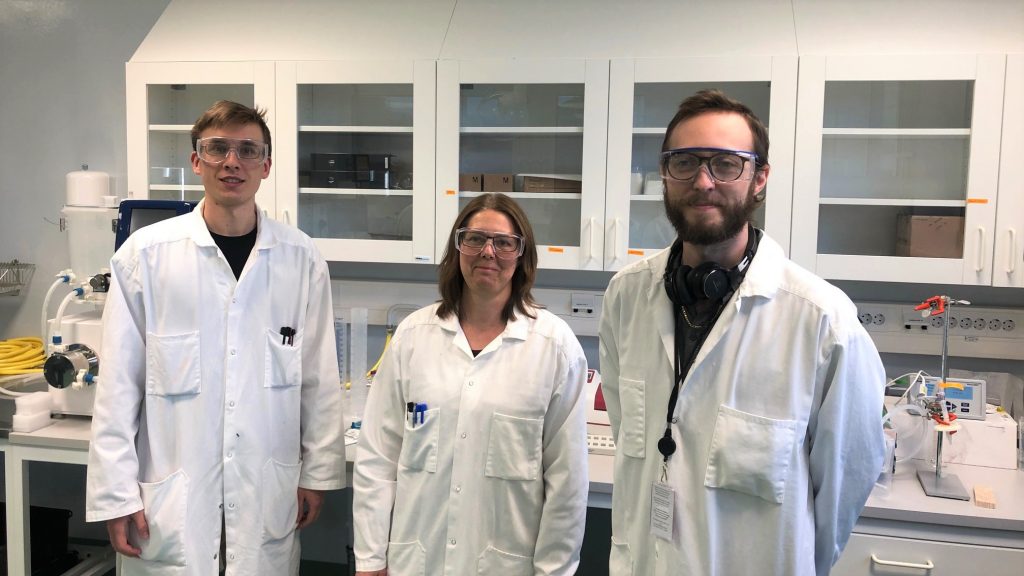

Jenny and two researchers from the company, Wojciech Kazmierczak and Martin Östberg, have now been at the Testa Center for three weeks to scale up the process. They have optimized their time by doing solid groundwork prior to their arrival and are currently very satisfied with their experience, not the least of which is the expertise they encountered and participated in at the Testa Center.

“It has been very easy to come into the Testa Center, and we have received very good support from the Testa Center team, such as getting help with packing large columns for the various chromatography steps. The main advantage of the Testa Center is that we have been able to use instruments that we do not have ourselves. We have now succeeded in scaling up the process ten-fold, which is of enormous value to the company. The weeks here have been important. It’s a big step forward for our continued development,” says Jenny Rönnmark.

The company, established in 2008, is based on Professor My Hedhammar’s research on spider silk proteins. The company develops, produces and commercializes products based on recombinant spider silk proteins. The main application areas are in medical technology, particularly cell culture and regenerative medicine.

Earlier this year Spiber started a collaboration with BioLamina, a company that has also been working at the Testa Center. Combining Spiber’s recombinant silk protein with laminins from BioLamina provides stem cells with a favorable 3D environment.

“This is a new technology in order to imitate the extracellular matrix (ECM). We get the 3D support from the silk and bio-relevance by adding laminins. This was an important collaboration for us that has led to our first product reaching the market, BioSilk521,” says Jenny Rönnmark.

There is a great interest in Spiber’s technology because they offer a way to grow primary cells, including stem cells, in a 3D environment in order to make complex tissue models. The company currently has several partnerships with world-leading academic research centers around the world.

“There are other companies that produce recombinant silk, but we are the only one able to bioactivate spider silk. Now that we have seen that we can produce the protein in a larger scale, we are moving toward an exciting future,” says Jenny Rönnmark.